A group of 15 specialist workers from Vauxhall’s Vivaro plant in Luton worked at Smiths Medical for 16 weeks as part of a consortium assembling and delivering more than 13,000 ventilators for the NHS. Hand-picked team were specifically chosen for their specialist skills and ability to carry out high-standard production work. Vauxhall staff worked alongside engineers and specialists from a range of industries on quality control, ensuring the ventilators met the high NHS standards. Vauxhall responded to Prime Minister Boris Johnson’s ‘herculean task’ of ramping up ventilator production 10-fold to combat Covid-19

In April, 13 staff plus a Team Leader and Supervisor, were handpicked from Vauxhall’s Kimpton Road Plant, which manufacturers the Vauxhall Vivaro van, to move to the Luton site of Smiths Medical, a division of Smiths Group plc, to help the company respond to the ‘herculean task’ of meeting the 10-fold increase in ventilator production described by the Prime Minister, Boris Johnson. The Vauxhall staff were picked for their specialist skills and ability to carry out intricate production work to a very high standard and time frame.

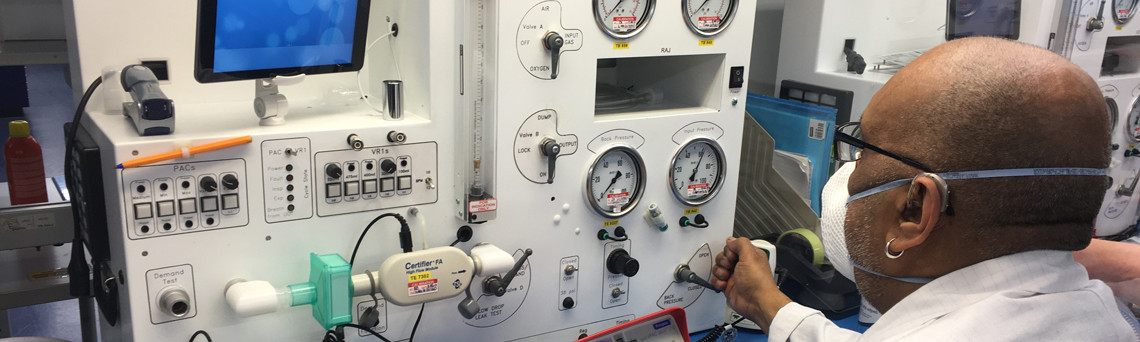

Following a week of training, the team helped to assemble 20 to 30 life-saving ventilator units a week. Towards the end of the assignment, production rose to hundreds of ventilators a week – surpassing all expectations. Vauxhall’s staff conducted in-line quality tests as the ventilators were produced, ensuring they met the high standards required by the NHS.

During their assignment, the Vauxhall staff worked alongside engineers and specialists from a variety of sectors, including aerospace and mobile phone manufacturers. The staff also managed to raise £300 for charity during their placement.

“I’m immensely proud and not at all surprised that Vauxhall workers have volunteered and have been able to make such a valuable contribution during these difficult times,” said Stephen Norman, Managing Director, Vauxhall Motors.

“Our plant employees are used to working on lines where only consistent high quality is not just essential but primordial, and they have done a fantastic job over the past 16 weeks being part of the team making much needed ventilators to contribute to the NHS. During the last war Vauxhall manufactured Churchill tanks in Luton and here we see our front line contribution in what is widely seen as the most serious world crisis since that time”

Julian Fagge, Strategy and M&A Director, Smiths Group, said: “On behalf of Smiths, I would like to extend our sincere thanks to Vauxhall for joining the fight against this terrible disease. This initiative has been part of the extraordinary efforts made by British industry to help maximise production of ventilators and save lives.”

The Vauxhall staff will return to their normal jobs at Kimpton Road Plant, which has since resumed full production capacity, running all three shifts.

Find us

Find us

Contact Us

Contact Us

My account

My account